- #SERVO MOTOR ARDUINO TURN CODE SERIAL#

- #SERVO MOTOR ARDUINO TURN CODE PRO#

- #SERVO MOTOR ARDUINO TURN CODE CODE#

The servo library manages much of the overhead and includes new, custom commands. Note that if you send a signal that is greater or lower than the servo can accept (for example, Firgelli linear actuators accept 1 to 2 ms), you might damage the actuator.Īnother option for controlling servos is to use the Arduino " servo library" (previously separate from the basic Arduino software, it is now included with V1.0). The relationship is linear, so use mathematics to determine the pulse which corresponds to a given angle.5V for 2500 microseconds = 2.5 milliseconds and corresponds to 180 degrees.

#SERVO MOTOR ARDUINO TURN CODE SERIAL#

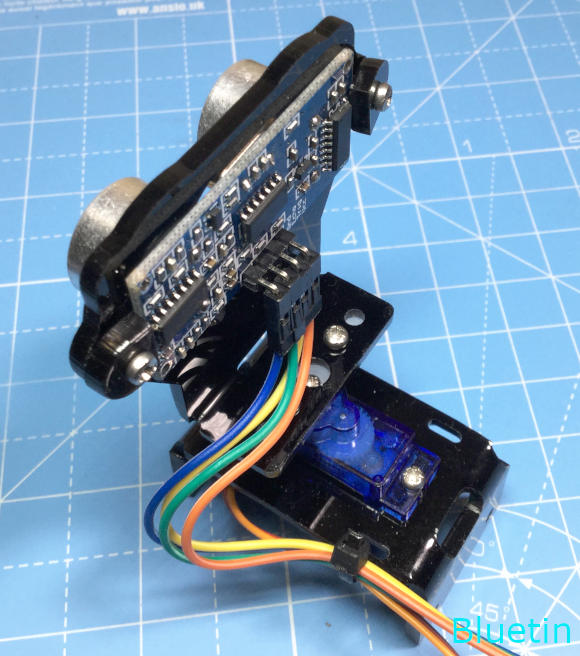

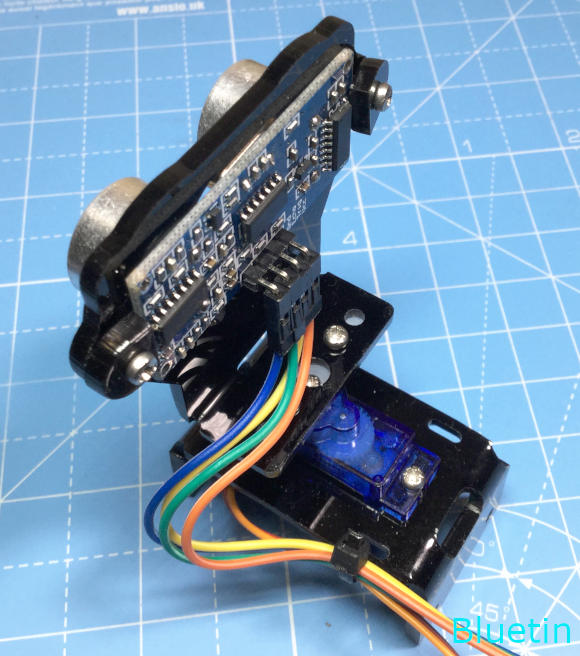

5V for 1500 microseconds = 1.5 milliseconds and corresponds to 90 degrees Arduino Servo Motor Basics and Control Maker Portal Arduino and MG90S Servo - Control via the Serial Monitor Watch on Arduino Servo Control - Using a Joystick to Turn a Servo Motor Watch on TSCA Electrical Group of Compa 1 week ago Hey, I read your article and your information is very amazing and so much helpful for me. 5V for 500 microseconds = 0.5 milliseconds and corresponds to 0 degrees. This pulse corresponds to a servo position, usually from 0 to 180 degrees. Servos operate by sending a timed +5V pulse (usually between 500us and 2500us) to the onboard electronics, which is repeated every ~20ms. It is best to use descriptive variables when coding to understand what each does, or the information it will contain. The term “pulse” is in black as it is not a reserved word and can be changed by the user. In this case, we called the pin “servopin” and assigned it a value of 4. This sets a pin number as dedicated input or output. Note that you also need to connect the batter's GND line to the Arduino's GND pins ("common ground"). If you want to use a more powerful servo, or if you want to connect it to a separate power supply, you would connect the battery / power supply's red (5V) and black (GND) wires to the servo's red and black wires, and connect the signal wire to the Arduino. Connect the yellow or white wire from the servo to a digital pin on the ArduinoĪlternatively, you can plug the servo's wire into three adjacent pins, and set the pin connected to the red lead to "HIGH" and the pin connected to the black lead to "LOW". Connect the red wire from the servo to the +5V pin on the Arduino. Connect the black wire from the servo to the GND pin on the Arduino. When powering the servo directly from the Arduino board: The following example uses a standard sized servo (without any load) powered directly from the Arduino via USB. However, a servo motor may require significantly more current than the Arduino can provide. Myservo.Controlling a servo motor directly from the Arduino is quite easy.

Here my latest attempt.įor(pos = 0 pos < 180 pos += 1) // goes from 0 degrees to 180 degrees

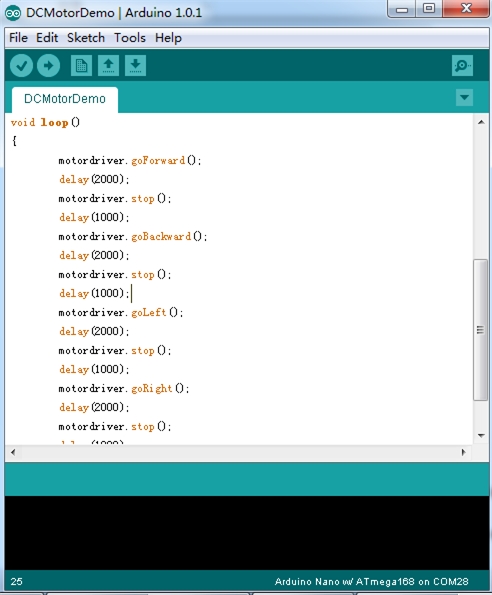

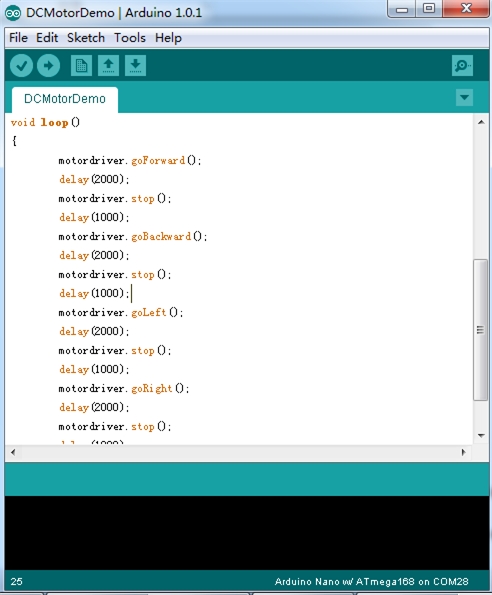

Soldering…setting up bluetooth…all very exciting. Myservo.write(pos) // tell servo to go to position in variable ‘pos’ĭelay(15) // waits 15ms for the servo to reach the position Myservo.attach(9) // attaches the servo on pin 9 to the servo objectįor(pos = 0 pos =1 pos-=1) // goes from 180 degrees to 0 degrees Int pos = 0 // variable to store the servo position a maximum of eight servo objects can be created Servo myservo // create servo object to control a servo

#SERVO MOTOR ARDUINO TURN CODE CODE#

This example code is in the public domain. I am using this example and can make the servo turn…WOW.

#SERVO MOTOR ARDUINO TURN CODE PRO#

At that point I am done with the ardunio pro and would like to kill power to the servo until it is need the next show. I just want my servo to turn 90 degrees then stop.

0 kommentar(er)

0 kommentar(er)